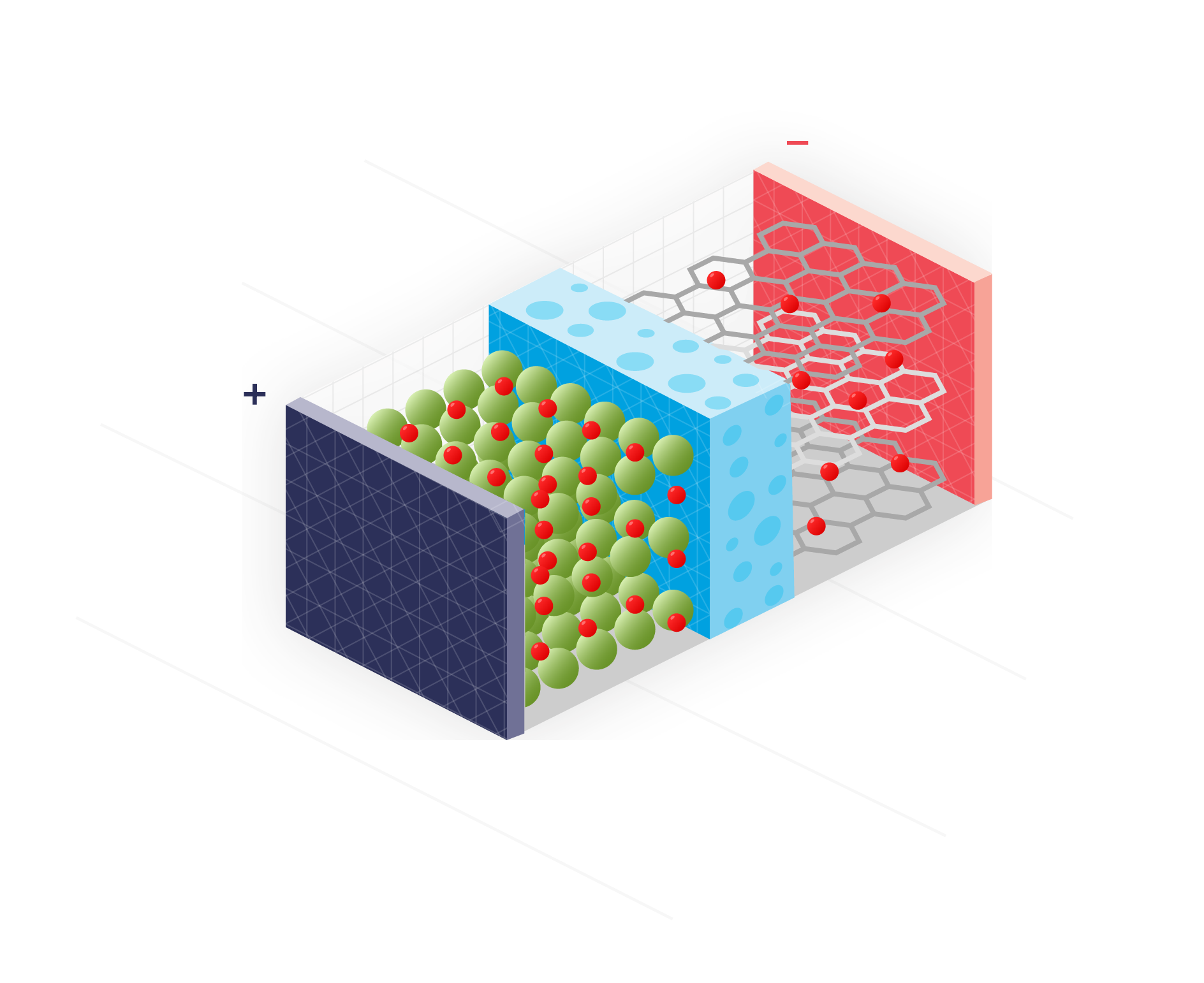

A better way to build a Li-ion battery.

Miltec develops technology for the manufacturing of

Li-ion battery components using ultraviolet (UV) curable materials.

This makes battery production environmentally

friendly, safer, and more cost effective.

Harnessing the

power of UV.

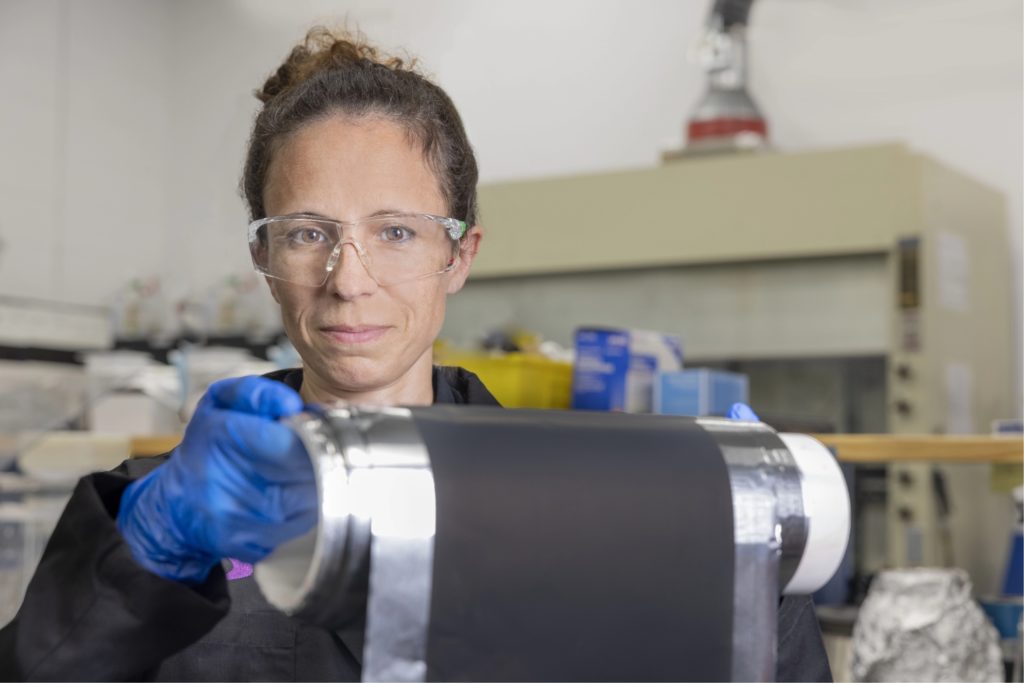

When Li-ion battery components are treated with UV

curable binders and coatings, they have the same or

improved performance over traditional manufacturing,

and are safer to build. Miltec develops the UV

technologies that make better batteries possible.

What is UV Curing?

UV curing is an eco-friendly process that uses UV light instead of thermal energy to quickly and permanently cure materials used in electric vehicles, medical devices, electronics, power tools, grid energy storage, military, aerospace and other applications. The process of UV curing is safe, fast, and low-cost.

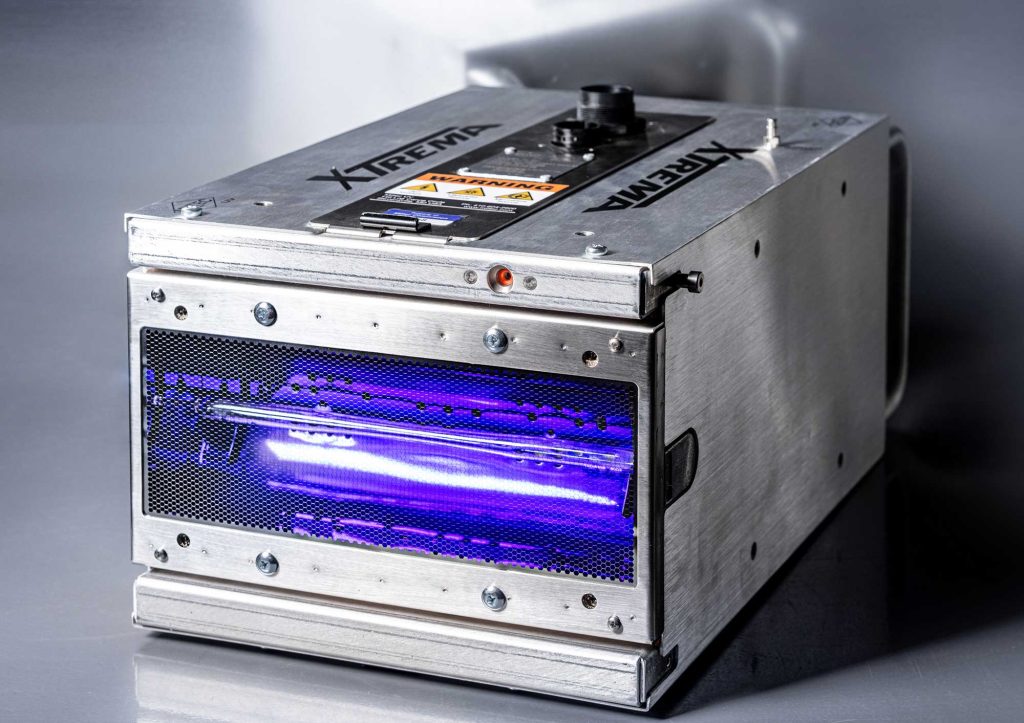

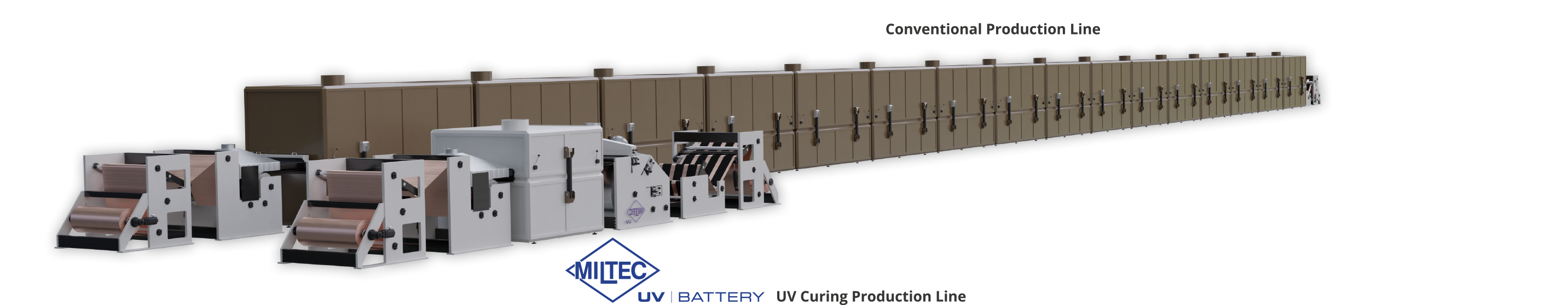

Big changes can

come in small

packages.

Efficiency, safety, and cost savings aside, Miltec UV

curing equipment boasts a dramatically smaller

factory footprint and carbon footprint when

compared to conventional systems.

Lead the charge in

Li-ion battery technology.

The Li-ion battery industry is transforming. Miltec is proud to offer innovative UV solutions that answer the call for a smarter, faster, cleaner production process. Making the switch to stay ahead of the game is simple, and it can all start with an evaluation.

Not ready yet?