Put battery production into overdrive.

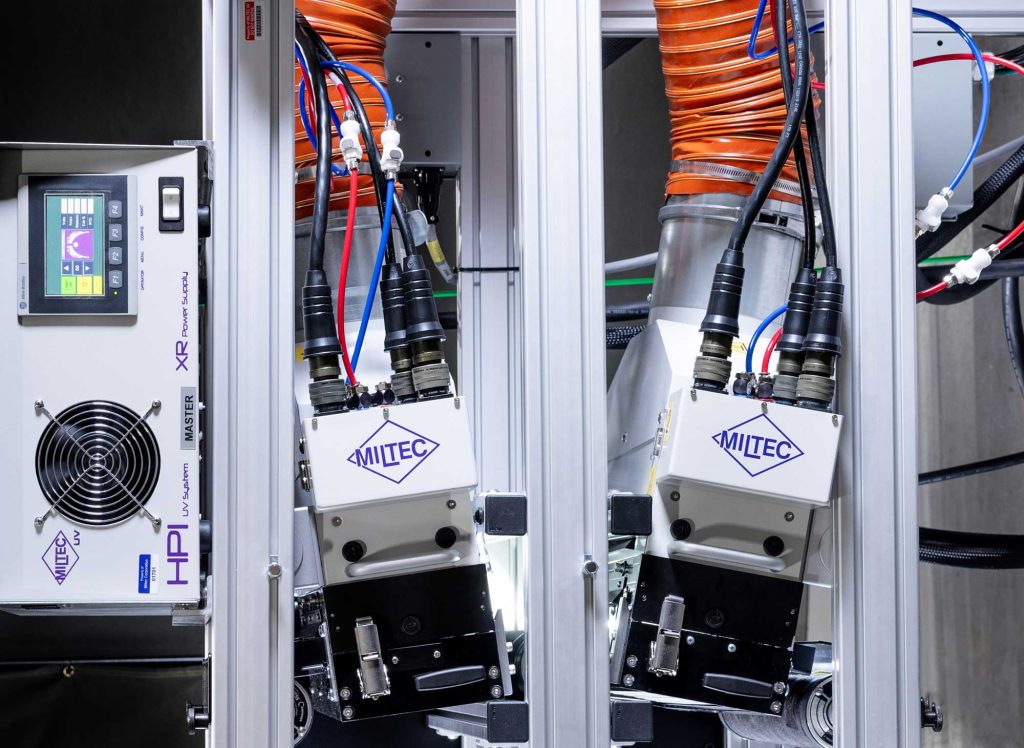

Our advanced technology includes patented UV binder chemistries

and UV curing equipment that help manufacturers build batteries

faster, and more efficiently with enhanced safety.

From start ups to large manufacturers, our experts in

UV curing equipment and binders collaborate with machine

builders around the world to integrate and create full-scale

UV curing systems that eliminate the need for NMP.

Miltec’s UV curable cathode binders are compatible with all

active materials including NMC, NCA, LFP, LCO, LMO and S.

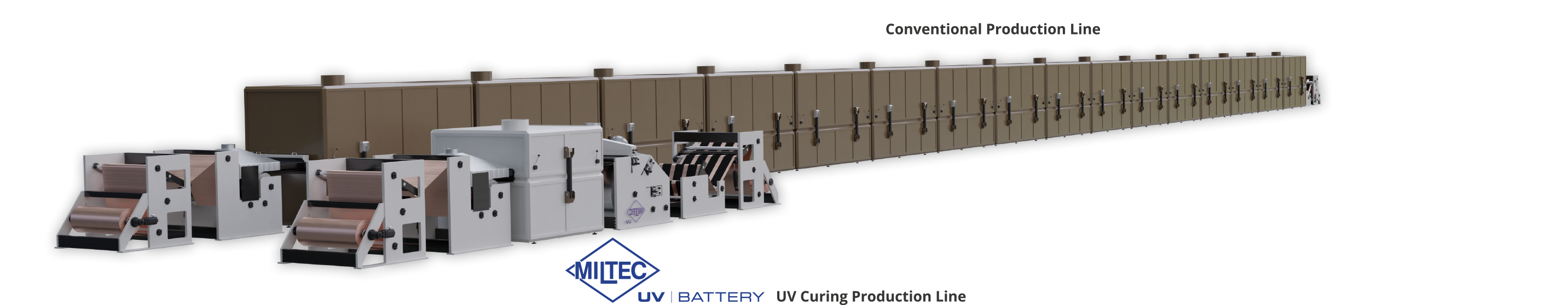

80%

reduction in production

line length

Smaller, speedier,

and just as mighty.

UV curing equipment boasts a dramatically smaller factory

footprint when compared to conventional systems. And since

it does not rely on a long line of thermal drying ovens,

production speed increases; cathodes can be cured at a

rate of up to 100 m/minute.

Easier on the environment.

Safer for your team.

The UV-curable binders used in our process don’t rely on NMP and require significantly shorter thermal dryers. By avoiding toxic and flammable solvents, we help reduce environmental impact and improve employee safety.

Learn more about NMP and the future of Li-ion battery production. Read our blog.

Significant savings

from every angle.

UV curing equipment gives you a reduced production footprint and faster line speed, and uses just 1/10th the energy of conventional systems. The result is an 85% reduction in production cost.

85%

reduction in production

cost

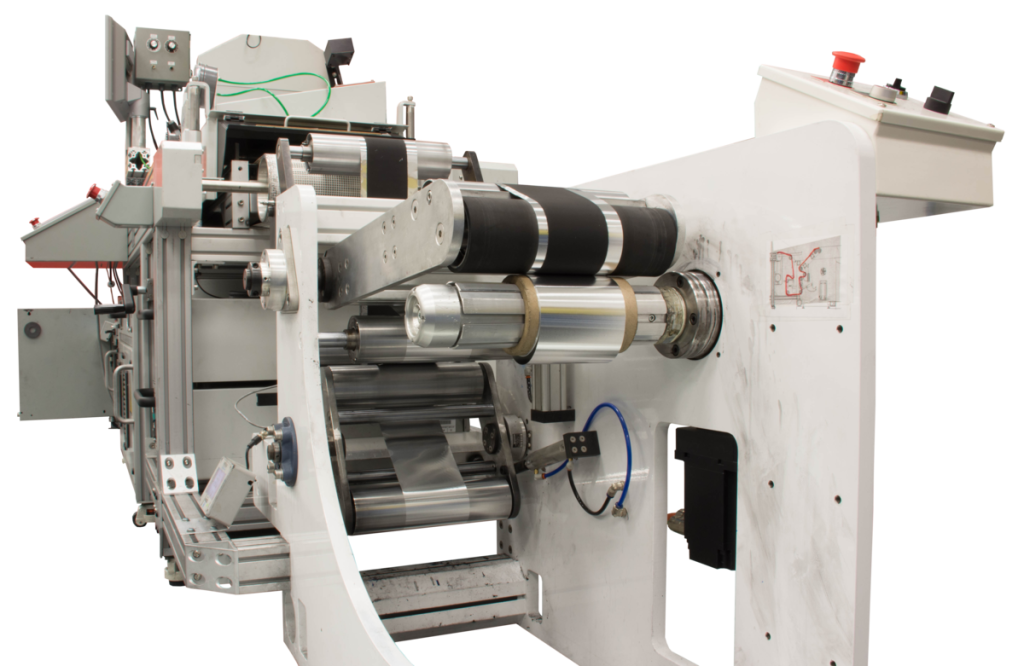

Test our system with your

application.

Miltec’s system can be retrofitted onto your existing production line, or it can be

integrated into a new cathode coating line. But making the switch can start

with a trial evaluation. Schedule an evaluation to learn how you can test the

production system with your application and see measuarable results.